Environmental management

Yaskawa Group Environmental Policies

We established the Group Environmental Policy in fiscal 2015 in order to accelerate global environmental initiatives, including those of overseas affiliates.

Environmental Philosophy

Based on the Management Principles of the Yaskawa Group, we recognize that the conservation of the global environment is one of the most important issues for all humankind. In every stage of our business operation, we contribute to the realization of a sustainable society through our proactive environmentally conscious actions.

Environmental Action Guidelines

- Participation by everyone

We strongly believe that we all should participate and take responsibility in order to achieve realization of biodiversity conservation, and a low-carbon and recycle-based society.

- Environmental contribution by innovative technologies

For the future prosperity of society, we will contribute to the improvement of the global environment through our products and services developed by technological innovation that will be useful in a wide range of applications in communities worldwide.

- Environmental consideration of products and services

We strive to reduce the environmental impacts of our products and services, for their entire life-cycle, from research and development, product design, procurement, manufacturing, distribution and usage through to end-of-life handling.

- Aiming for future-oriented goals and objectives

We aim to heighten social and environmental excellence not only by complying with applicable environmental laws and regulations but also by establishing our own future oriented goals and objectives. We will continue to improve our environmental management and to endeavor to minimize environmental risks.

- Improvement of environmental awareness

We strive to improve environmental awareness among all of us by education and enlightenment about our relationship with the environment from a broad perspective so that each of us can independently implement the environmental activities.

- Information disclosure and communication

We are committed to disclosing information about our environmental activities and communicate proactively and openly with stakeholders for deep mutual understanding.

Organization for Environmental Promotion

Yaskawa and affiliated companies have continued to promote the environmental programs in accordance with group-wide policies and implementation plans that have been deliberated and decided by the Company-Wide Environmental Promotion Committee.

The Group’s Environmental Management

The Group Environmental Policy is incorporated into the environmental targets of each affiliated company, and environmental activities are carried out in accordance with the business contents.

Yaskawa began acquiring ISO 14001 (Environmental Management System) certification for its manufacturing facilities in 1998, and we acquired integrated certification for our manufacturing facilities in Japan in 2014*1.

We are also expanding the scope of certification to include Group companies, and we will continue to promote environmental management globally based on ISO 14001.

*1 Scope of ISO 14001 at Yaskawa: All stages of manufacturing activities, products, and services in the departments of the Iruma Plant, Yahata-nishi Plant, Nakama Plant, Yukuhashi Plant, and Yahata-higashi Plant and in affiliated companies on the premises of those plants.

List of ISO 14001 Certification for Group Companies

Compliance with Environmental Regulations

In FY2024, one product model was found to be non-compliant with the RoHS directive.

We promptly reported the issue to customers and regulatory authorities, took legally appropriate action, and completed corrective measures.

On-Site Check of Waste Disposal Companies

With the focus set on the responsibility of the waste generator, we perform, by use of our common audit check sheets, on-site checks of waste collection/transport companies and disposal companies under contract with our production plants.

Until FY2024, none of our contractors have violated laws and regulations. We will continue to perform these checks in the future.

Environmental Communication

The Yaskawa Group discloses information on its environmental activities and actively communicates with stakeholders to deepen mutual understanding. We are also disseminating information on our environmental initiatives and views widely through our integrated report and website, and will continue to strengthen our efforts.

Disclosure of Information to Third Parties

We disclose information on the Yaskawa Group’s initiatives and environmental impact data to a variety of stakeholders, including government agencies and industry groups, as well as through CDP’s survey on climate change and water security and “SDGs management“ survey conducted by Nikkei Research.

To improve the reliability of the calculated greenhouse gas emissions (Scope 1, 2, and 3), we receive third-party verification by SGS Japan Inc.

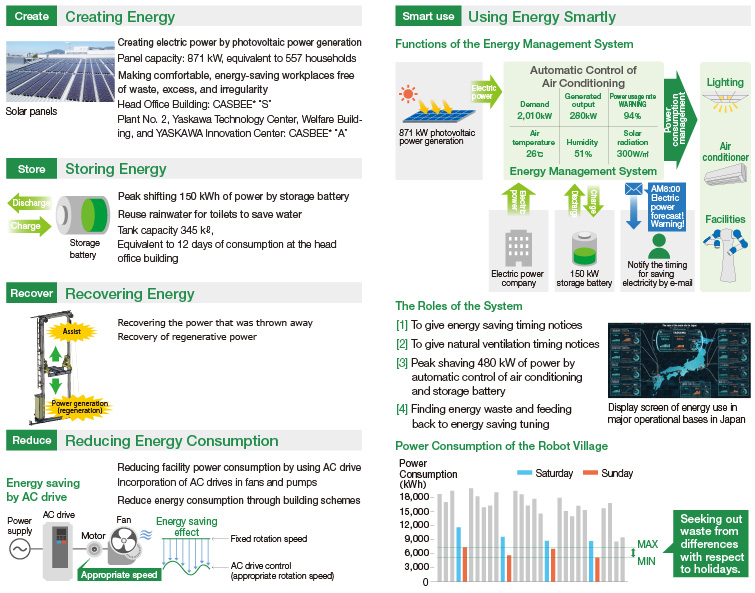

Environmental-Friendly Features of Robot Village*2

The Yahata-nishi Plant “Robot Village” in Kitakyushu has been implementing the “Clean Power 100 Project,” an initiative to reduce CO2 emissions from electricity to zero by FY2021.

Robot Village focuses on five perspectives on energy: “create,” “store,” “recover,” “reduce,” and “smart use,” and also actively incorporates the Yaskawa’s own environmentally friendly technologies.

At the Yaskawa Technology Center, which opened in the spring of 2021, in addition to the building’s superior environmental performance, we are also working to improve the efficiency of energy use by introducing environmentally friendly technologies, including the installation of more than 70 AC drives, matrix converters, IPM motors, and other Yaskawa environmentally friendly products, as well as solar power generation.

As a result of advancing the adoption of CO2-free electricity, we achieved zero CO2 emissions from electricity consumption at the Robot Village.

The environmental technologies used in the Robot Village are explained in an easy-to-understand manner to visitors of the Yaskawa Innovation Center.

In-house technology in the Robot Village

Received the Energy Conservation Grand Prize

Robot Village was awarded the Energy Conservation Center Japan chairman’s prize in the 2015 Energy Conservation Grand Prize. In the products and business model category, it also received the minister’s prize, Ministry of Economy, Trade and Industry, for Yaskawa Matrix Converter U1000.

Other awards and prizes

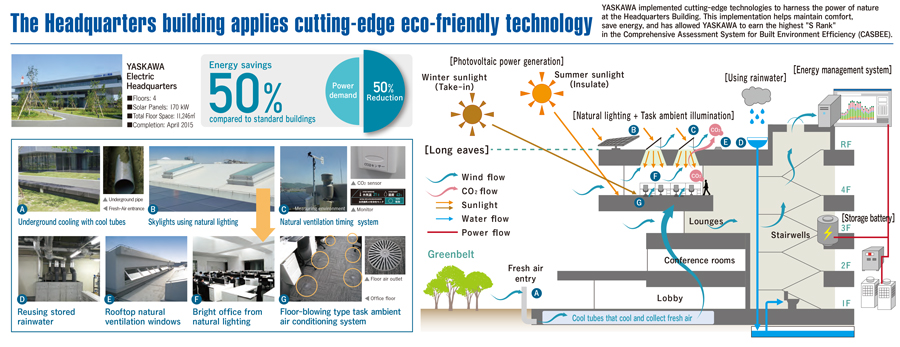

The head office building of Yaskawa Electric received the FY2017 Carbon Neutral Grand Prize*3.

Even after completion of the project, energy conservation operations have been thoroughly carried out and a 76% energy cut was implemented in comparison to standard buildings.

The head office also received the Kyushu Bureau of Economy, Trade and Industry’s Director General Award at the 2019 Excellent Energy Conservation Factory & Building Awards competition for its everyday energy-saving activities.

*3 An award system has been implemented annually by the Japanese Association of Building Mechanical and Electrical Engineers. It aims to contribute to building a “carbon-neutral” society in which CO2 emissions by buildings are reduced to nearly zero.

Commitment to environmental protection (Germany)

YASKAWA EUROPE GmbH ROBOTICS DIVISION in Germany obtained ISO 50001 certification in December 2016. We have improved energy performance by implementing energy-saving measures.

YASKAWA EUROPE GmbH ROBOTICS DIVISION uses an energy management system that delivers data on energy use and efficiency in a visual format. We save energy by reviewing work procedures and eliminating redundant processes.

In FY2019, (YEU)R reduced energy consumption by 3.11% compared to FY2018. We are also undertaking “2019 -2021 Energy and Environment Campaign” to raise employees’ awareness on environmental conservation and energy savings. We created a sticker featuring the catchphrase “Green YASKAWA Footprint” for the campaign.

Our first target was to reduce the inflow of outdoor air into heated rooms. We attached stickers near thermostats for radiator heaters to raise awareness of temperature settings. The latest target we set was to reduce paper use in printing and energy use in lighting, attaching the stickers to printers and light switches.

These activities have been effective in raising employees’ awareness on energy conservation. We are planning to install a monitor that displays the status of energy consumption obtained by the energy management system with software measuring data in real time in more areas at (YEU)R. We are aiming to reduce our environmental load further by enhancing employees’ awareness on energy conservation.

ISO50001 is the international standard for energy management and is designed to help organizations in all fields and sizes to manage energy use and improve energy performance continuously.

Commitment to environmental protection (India)

In May 2025, Yaskawa India received the Best EHS Practices Award at the National EHS (Environment, Health & Safety) Excellence Awards 2025, hosted by the Confederation of Indian Industry (CII).

This award recognizes Yaskawa India’s world-class EHS practices and outstanding efforts in sustainability, health, and workplace safety.

Among over 450 participating companies, Yaskawa India earned high marks through the following evaluation process.

– A two day on-site review by CII expert auditors

– A scoring system based on innovation, legal compliance, and social impact

- The following key initiatives led to the award.:

- 1.Energy efficiency and CO2 reduction: With the U1000 test bench, energy consumption during motor testing was reduced by 30% and annual CO2 emissions were reduced by more than 250 tons.

- 2.Zero waste to landfill policy: Achieved 100% reuse of waste through recycling, upcycling, and waste-to-energy conversion. Plastic neutrality was also achieved.

- 3.Industry-leading safety measures: Recreated high-risk environments at the Safety DOJO experiential training facility. Reduced disaster risk through predictive analytics.

- 4.Commitment to environment and safety beyond standards: Maintained an air quality that is 20% better than legal standards. Saved 1.5 million liters of water annually by using a closed-loop water circulation system.

Additionally, a comprehensive employee wellness program has been introduced, covering ergonomics and mental health.

This award is a testament to the dedication of every Yaskawa India employee and reflects our unwavering commitment to “Safety First”.

We will continue to fulfill our responsibilities to people, the planet, and productivity.

Certified as Leading Company in Decarbonization under the “Kitakyushu Certification System for Decarbonized Energy” (Yahata-nishi Plant and Kokura Plant)

On March 30, 2022, our Yahata-nishi Plant and Kokura Plant, which are located in Kitakyushu, were certified under the “Kitakyushu Certification System for Decarbonized Energy” as a Leading Company in Decarbonization for their early adoption of CO2-free energy.

Aiming to become a zero carbon city by 2050, Kitakyushu promotes the use of renewable energy through its Kitakyushu Model for 100% Renewable Energy that aims to have all public facilities make the switch to 100% renewable energy by 2025. The main purpose of this certification system is to accelerate the decarbonization trend by urging companies in the city to join in as well.

Certified companies receive perks such as a “certification sticker and logo.”

-

Certificate

-

Certification Logo

-

Certification Sticker

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management