HINODE,Ltd. which manufactures lifeline-related cast iron products such as manhole covers for water and sewage system

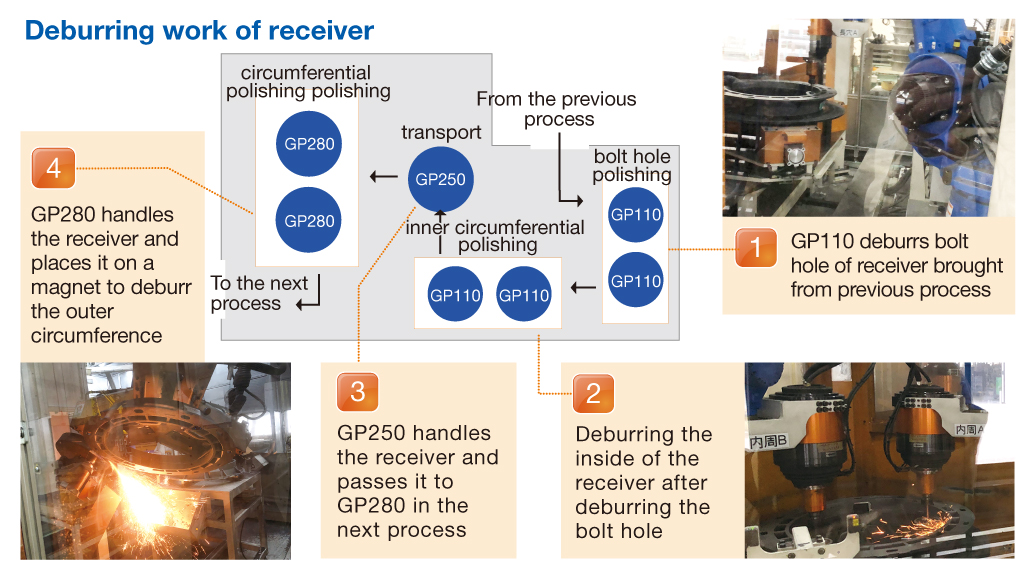

Yaskawa’s robots are used to deburr the frame of manholes.

The Saga Plant of HINODE manufactures various types of manhole covers and frame. Conventionally, deburring work has been done by hand, but due to the heavy materials and the environment in which sparks and iron powder fly, it has put a burden on workers.

The installation of Yaskawa robots has reduced the burden on workers and shortened the cycle time by halving the work time, while also stabilizing the quality.

In addition, we were able to manufacture a wide variety of products without altering the arrangement of the robot’s work.

Benefits of introducing robots

– The manual work time has been reduced by half and the cycle time has been shortened.

– In addition to solving the labor shortage, reducing the burden on workers from the environment such as sparks and iron powder flying

– Quality equalization and stabilization

Customer’s voice

We decided to introduce a robot by Yaskawa based on our belief that robots with minimal preparation and automated facilities have an advantage in responding to our strength of “low-volume, high-variety production.”

We had a lot of discussions with the person in charge of Yaskawa about the problem of how to accurately and flexibly handle the burr that is removed by a considerable amount of weight from the receiving frame compared to the cover, and how to make the robot handle the burr against the grindstone. We also studied how to achieve multi-product production with jigs and tools without changing the arrangement of robotic work.

Company Profile

HINODE,Ltd.

Saga Plant Global Innovation Center

Address: Aza Iwasaki, Oaza Harakoga, Miyaki-cho, Miyagi-gun, Saga, JAPAN

Business: R & D, manufacturing and sales of public buildings, industrial machinery, etc. utilizing material technologies such as cast iron and polymer concrete

URL : https://hinodesuido.co.jp/(Japanese only)

Installed products

Here are some other examples.

RoadPrintz Inc.

-Road painting system by truck mounted with robot

Yasuda Yogurt Co., Ltd

-Yogurt Cartons Palletizing

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management