Product safety & quality

The Yaskawa Group Code of Conduct sets forth the following standards for product quality and safety. The Company

is committed to thorough safety and quality control from a customer-oriented standpoint, responding to customer

feedback in a timely and appropriate manner, and making continuous improvements to further enhance customer

trust.

- We strive to improve our quality control system and update our technical development and technical platform,

while complying with our company rules, in order to ensure the quality and safety of the products we provide.

- We respond appropriately to end users’ requests and inquiries in a timely manner upon the basis of confirmation

of the facts.

- We create catalogs, product descriptions, adverts and so on that are easy for end users to understand and place

customer safety first. We also strive to continuously improve product description documents.

- To ensure safety, quality and reliability in the product development process, we base our operations and reviews

on the end user’s perspective.

Product safety

In order for customers to use our products with confidence, we believe that ensuring product safety at the source

is of the utmost importance. For this reason, in the product development stage, we conduct risk assessments to

ensure the safety of our products, as well as compliance with various international standards, verification, and

safety review meetings.

We also conduct in-house education and awareness activities for Product Liability, and as part of our “bud of PL”

*1 activities, we are raising awareness of issues related to safety both inside and outside the company, and are

constantly pursuing ongoing activities aimed at higher targets.

*1 “bud of PL” activities are a collective term for activities aimed at cultivating a culture of product

responsibility, fostering a product safety culture, and improving product safety. These activities aim to

pinpoint “seeds of the PL problem” inherent in our company products from near-miss incidents (A case in which an

accident did not occur, but the situation was frightening and startling) and accident information of other

companies’ products.

Quality assurance system

In order to provide optimal services to customers, the Yaskawa Group has established quality assurance

departments in each of its business divisions and built a global quality assurance system by sharing quality

information with local subsidiaries.

The Quality & Service Division of the Head Office, in cooperation with the Quality Assurance Departments of

each business division, plans and promotes the optimization of quality assurance activities throughout the

Yaskawa Group.

In conducting various activities, we aim to maximize customer value based on TQM, the corporate management

foundation.

Product risk management

Our company engages in quality assurance activities throughout the product life cycle, from the planning stage

through development, mass production and marketing. These activities are covered by a company-wide QMS system

based on ISO standards, which extends from the company-wide level to the level of actual activities of providing

products and services of each division.

At the product realization stage, we ensure quality by preventing the recurrence of development, production, and

market problems that have occurred in the past, preventing them in advance by complying with FMEA, risk

assessment, and various safety standards, and conducting thorough verification of them. At the production stage,

we ensure quality by conducting thorough testing and monitoring the quality status of each process. In dealing

with the market, we strive to detect and resolve problems as quickly as possible by integrating information on

problems pointed out by customers and on defects.

Among these, we place particular importance on product safety and compliance in order to prevent crises. In

addition to these preventative activities, in the event of a crisis, the Product Safety (PL) Committee and the

Compliance Committee have been established as a company-wide organization to ensure a unified response in the

event of a crisis. These activities are carried out in cooperation with the Quality Assurance Division. These

status of quality activities and monitoring indicators are reported to the Executive Committee on a regular

basis and shared throughout the Company to accelerate and improve initiatives.

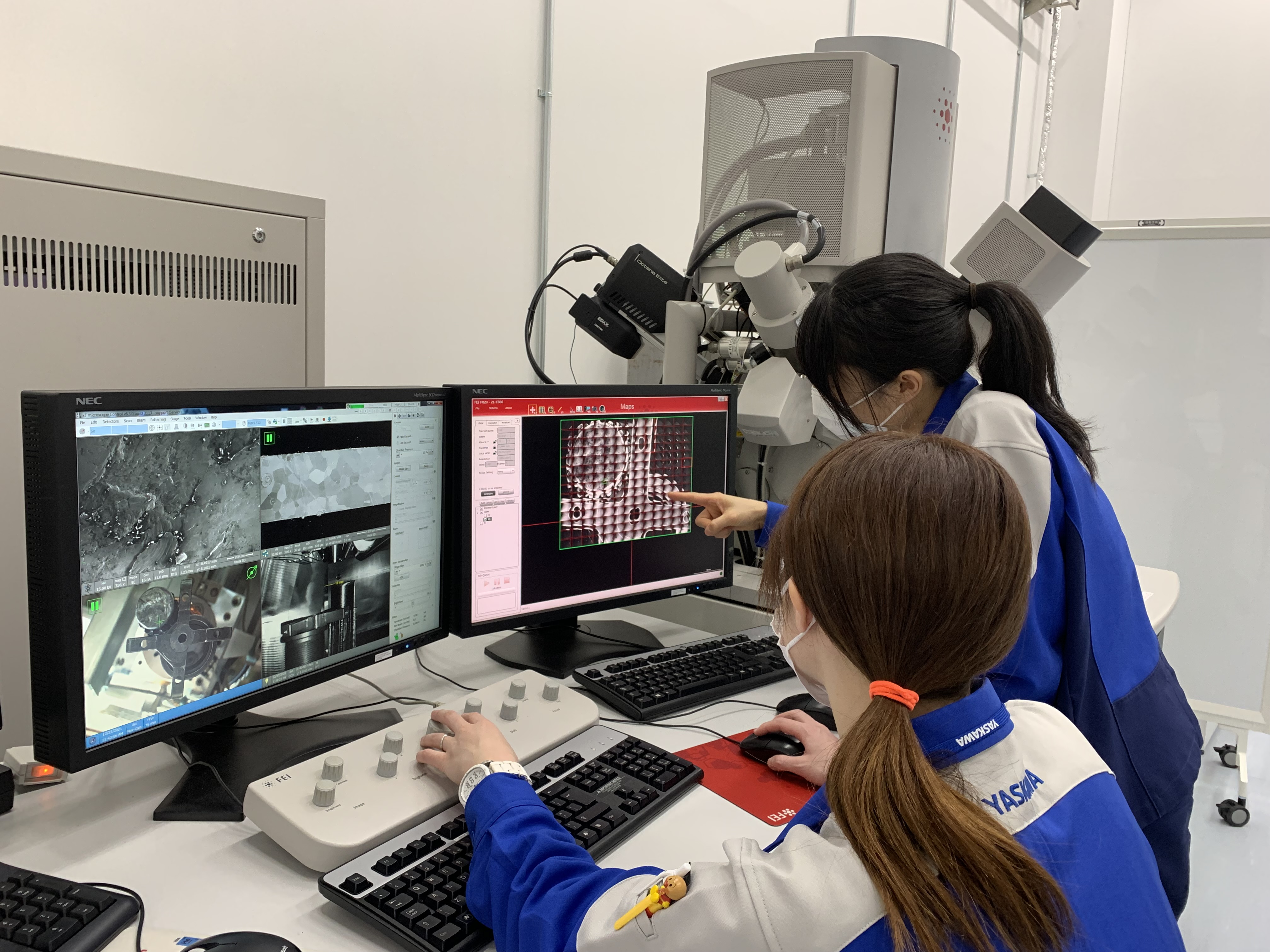

Activities to improve quality and reliability

Under the slogan of “Creating products that do not break by actually breaking them,” we conduct our own limit

tests and environmental resistance tests at the development and design stages, based on various stresses such as

heat, vibration, corrosive gases, dust, and oil mist at the component or product level. We are also working on

the development of a non-defective analysis technology that can evaluate the reliability of electronic

components in a short time based on internal structural evaluation.

Quality improvement

Defects information from customers is collected and analyzed online by Quality Information

System and reflected in quality improvement initiatives. In particular, this process leads to

cross-organizational deployment to prevent recurrence and initiatives to prevent problems during new product

development.

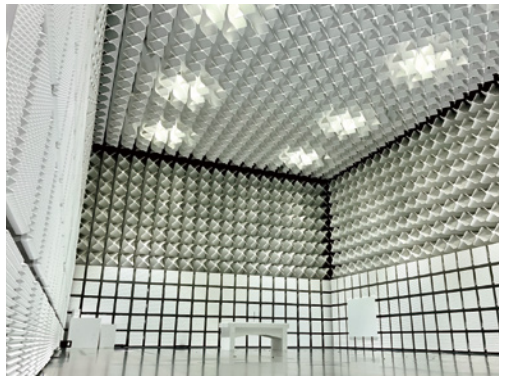

Compliance with International Safety Standards

Yaskawa strives to comply with international safety standards and laws, centering on “electrical safety” and “EMC

(electromagnetic compatibility) *2”, which are the core of safe products, and to optimize development quality

and speed by seamlessly implementing compliance with international safety standards through concurrent

engineering by effectively utilizing the certified test laboratories for functional safety technologies.

Yaskawa’s initiatives

・In fiscal 2017, an EMC test building was established at the headquarters, and the facility acquired ISO/IEC

17025 certification from A2LA, the American Institute of Laboratory Accreditation, and was registered as a TÜV

Rheinland and TÜV SÜD appointed test facility.

・In 2020, we obtained ISO/IEC 17025 certification, a public laboratory qualification related

to electrical safety standards, from the Japan Accreditation Board (JAB).

・With regard to functional safety technology, we plan and implement educational programs on functional safety,

such as “functional safety basic education” by internal experts and “machine safety education” by inviting

outside instructors, in order to improve the knowledge of technical personnel.

These activities will not only shorten the product development period, but also enable us to quickly supply safe

and secure mechatronics products to our customers.

*2 EMC: Abbreviation for Electromagnetic Compatibility: refers to the absence of negative effects on the

movements of other devices or systems caused by electromagnetic interference released by the motion of electric

or electronic devices, or the lack of impact received by electromagnetic interference from other devices or

systems to procure proper functionality in a continuous manner.

User school

For users to get the most performance out of our products and use them safely, the most important thing is basic

knowledge. We offer Motion Control School for customers of our AC drive and servo (general-purpose) products and Robot School for customers of our robots. We

teach two ways: the school-like training in which an instructor explains a product directly; and e-learning,

where customers learn over the Internet.

Test runs and after-sales service

Our engineers perform adjustments and test runs to ensure that our products are compatible with machines and to

increase the capacity of machines and equipment. In addition, Yaskawa group provides after-sales service on a

global basis, including support for preventive maintenance and investigation and repair of defects.

Lifetime service

We will continue to provide optimal services to keep our customers’ facilities and equipment running even when

normal services become unavailable. In addition to standard after-sales service, we will continue to provide

services that support our customers’ equipment by choosing the most appropriate method, such as reengineering,

renewal, and recycling.

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management