Yasuda Yogurt Co., Ltd., is a total manufacturer of fermented foods that produce, process, and distribute yogurt that focuses on the flavor and ingredients of fresh milk.

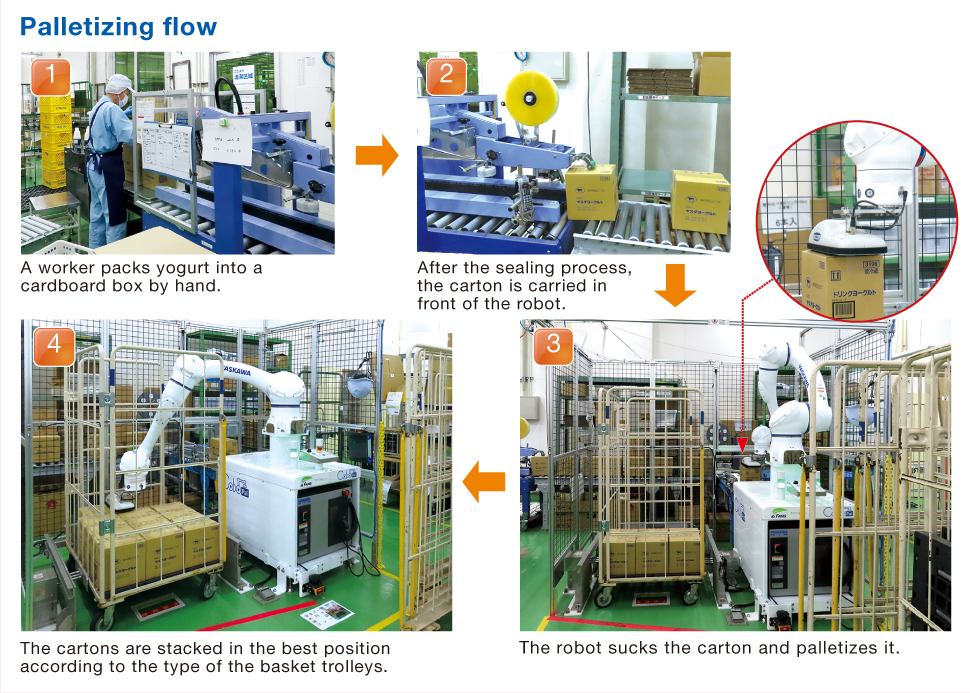

Yaskawa’s collaborative robot was adopted for stacking the cartons containing drinkable yogurt onto a basket trolleys.

Yasuda Yogurt Co., Ltd., labor shortages have been a management issue throughout the year, and workers have also been burdened by the heavy labor required to stack approx. 5.4 kg of cartons. This led to the adoption of Yaskawa’s collaborative robot (CoboPal, a palletizing system engineered by FAMS), allowing workers to set up in small spaces and operate without safety fences.

This company uses more than three types of basket trolleys, each of which is slightly different in size and material, so after testing and selecting sensors that fit the material, it was able to make stacking on different types of basket trolleys. As a result, the labor shortage was eliminated and the burden on workers was reduced.

Benefits of introducing robots

– Resolving labor shortage, equivalent to two workers

– Relieving from physical tasks, such as stacking approx. 5.4 kg of carton

Features of collaborative robot

– Can be installed in small places.

– Can be replaced by a human workspace without changing the layout.

– No safety fence and can work close to humans.

– Easy to clean with dustproof and drip-proof specs.

Customer’s voice

Our company’s products that focus on fresh milk have a short expiry date of around 20 days, so the factory operates all year around. Additionally, due to its location far from the center of the town, labor shortages were a problem throughout the year.

We decided to adopt the system because of the feeling that we would solve the labor shortage and automate the palletizing work, which is hard work and physical burden for workers, when FAMS, which had been communicating with us for some time, introduced a new package that includes teaching and teaching robots, 24-hour monitoring service, and maintenance.

During the installation process, there were various challenges such as efficient palletizing work in a limited space, dealing with three different types of basket trolley, and ensuring a speed that does not stop the production line. Each time, we worked with the person in charge to adjust and improve the line and program.

As a result, there are now almost no programmatic downtime cases. We are willing to consider the adoption of robots in other small capacity lines, despite the space challenges.

Company Profile

Yasuda Yogurt Co., Ltd.

Address: 940 Hota, Agano, Niigata Prefecture, JAPAN

Business: Dairy products manufacturing and sales

URL : http://www.yasuda-yogurt.co.jp/(Japanese only)

Installed products

Here are some other examples.

RoadPrintz Inc.

-Road painting system by truck mounted with robot

HINODE,Ltd.

-Deburring of Manhole Frame

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management