Green process

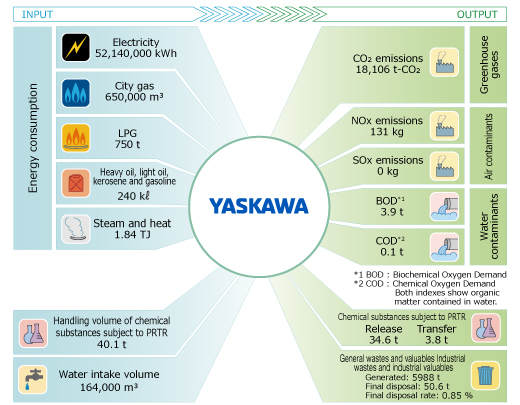

Environmental Impact Data Summary (FY2023)

-

[Range of applicability of data]

Yaskawa Electric and group companies and partners within Yaskawa Electric business sites, Yaskawa Motor Corporation

However, the ranges of the following items are defined separately.

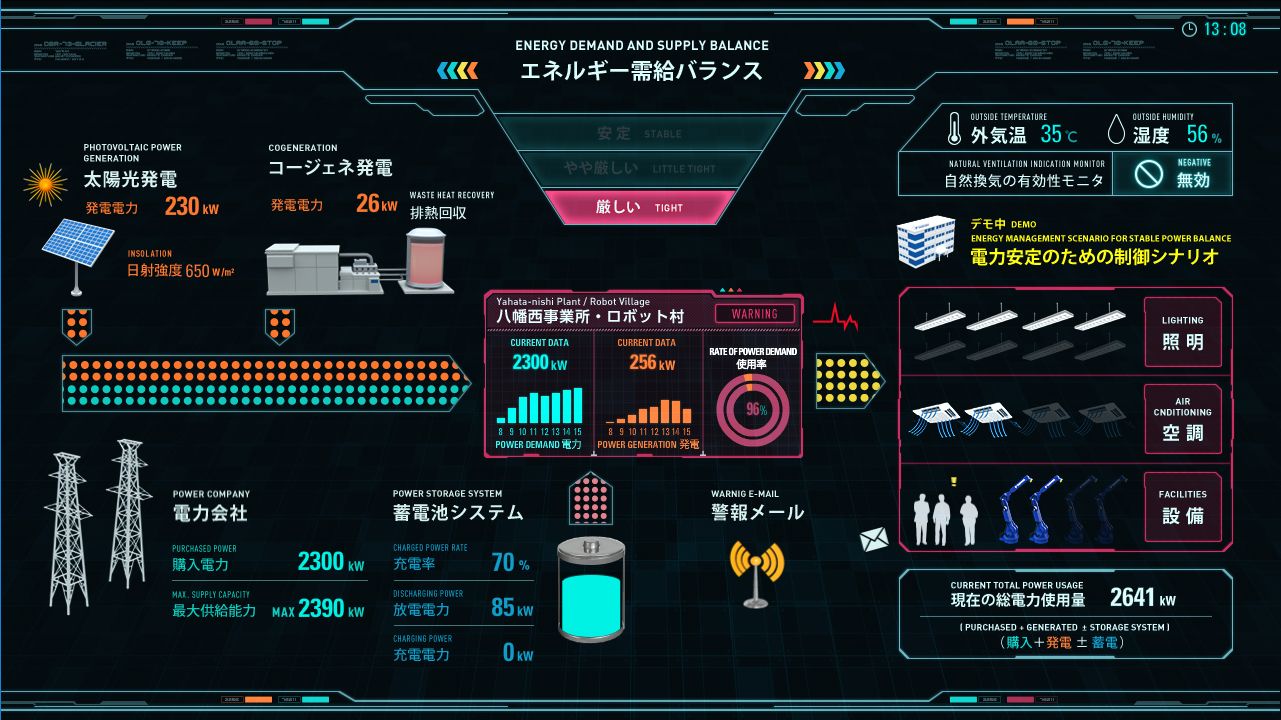

“Green process” to reduce the burden on the environment in business activities

The Yaskawa Group emits CO2 and waste materials as a result of using energy, such as electricity, gas, etc., and resources, such as components/materials, water, etc., for manufacturing, sales, engineering, etc., of electrical products and systems, and other related businesses.

The above figure illustrates the status of environmental loads of our production and sales activities.

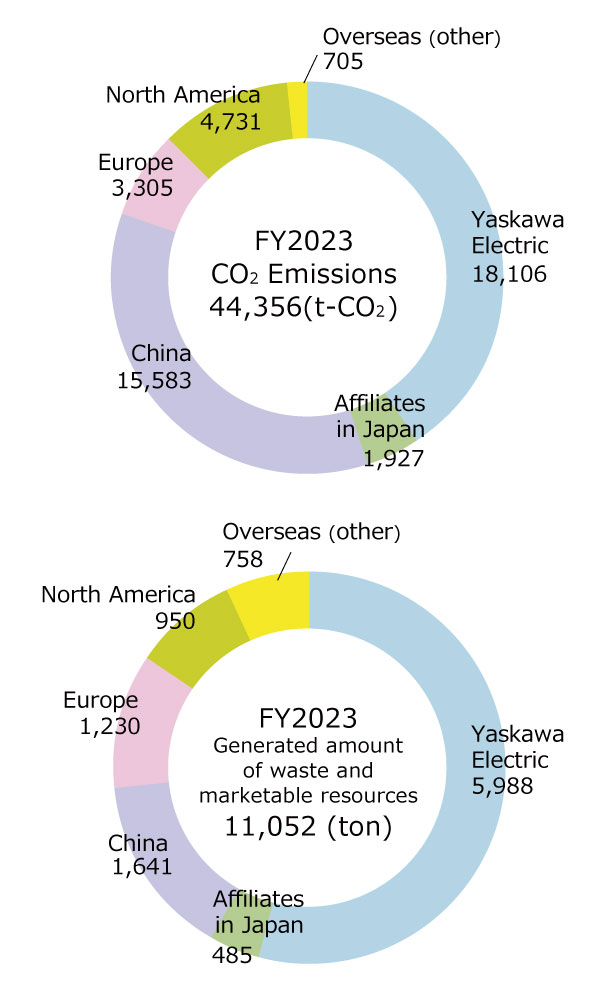

We also manage the amount of energy used, CO2 emissions, and amounts of waste materials and valuables generated from business activities of our domestic and international group companies.

The scope of management targets group companies of high energy usage amount (accounting for approximately 99% of the energy used by the entire group).

Going forward, we shall expand the scope of management to 100% and promote the reduction of environmental loads.

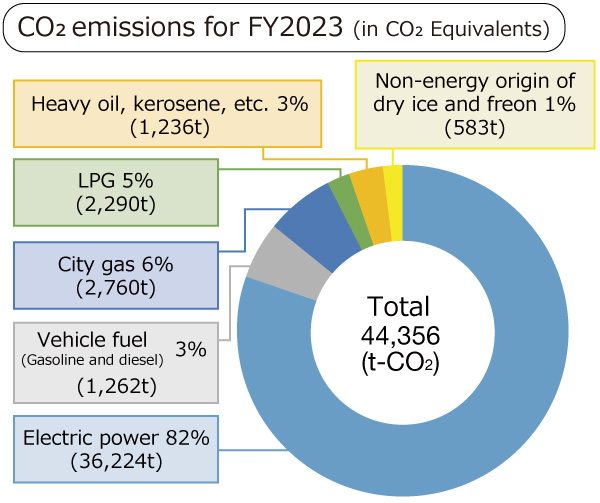

The graph at the right shows the energy-derived CO2 emissions of the Yaskawa Group in FY2023.

Measures against Climate Change

Initiatives to Save Energy

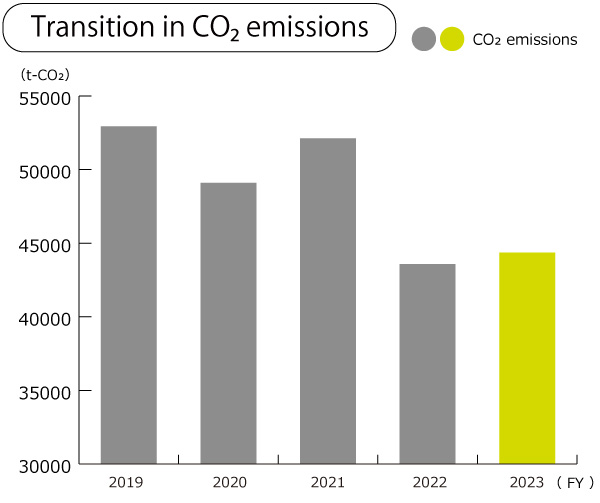

Yaskawa engaged in energy-conservation activities with the aim of reducing total Group CO2 emissions by 12% (compared to FY2018), as per the target in the 2023 Midterm Environmental Plan.

In FY2023, Yaskawa mainly advocated for improvements to investigate and prevent air leakages, as well as upgrade lighting, air-conditioners, and production equipment. Overseas group companies also implemented solar power and promoted energy saving.

-

-

*Actual emission factors released by electric power companies were used until FY2018 to calculate CO2 emissions from electric power in Japan. Adjusted emission factors are used from FY2019 onward.

*For calculation of CO2 emissions from electric power overseas, the representative emissions factor of each country (see IEA data) is used.

[Range of applicability of data] Yaskawa Group

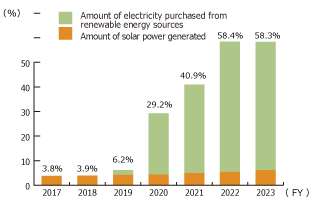

Initiatives to Decarbonize Electricity

Under its 2025 Midterm Environmental Plan, the Group aims to reduce CO2 emissions by 30% (compared to FY2018) and reach a CO2-free energy rate of 75% or more in electricity usage. We completed the adoption of CO2-free energy at Iruma Plant, in addition to Yahata-nishi Plant, Nakama Plant, and Kokura Plant. As a result, CO2-free energy makes up approximately 58% of our energy consumption.

Next, we plan to adopt CO2-free energy at Yukuhashi Plant.

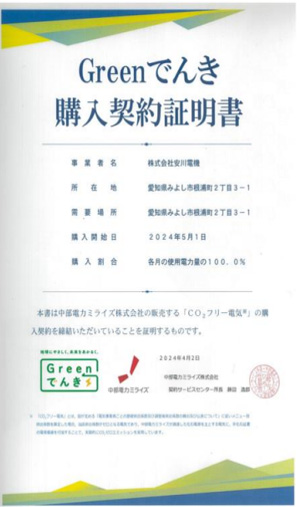

Achievement of Carbon Neutrality (zero CO2 emissions) at the Chubu Robot Center

Chubu Robot Center CO2 Zero Power Certificate

In May 2024, the Chubu Robot Center entered into a contract for the CO2-free plan offered by Chubu Electric Power. The electricity purchased now is generated without CO2 emissions in accordance with non-fossil fuel energy certificates. Since electricity accounts for 100% of the plant’s energy, the Chubu Robot Center is Yaskawa’s first site to achieve zero CO2 emissions. The certificate granted for using zero CO2 energy is posted at the entrance of the Chubu Robot Center.

Startup of Solar Power System at Robot Plant No.4

The solar power generation system at Plant No.4, which was completed in August 2023, has started operation. The solar panel capacity is 822 kw, the largest of Yaskawa’s solar power systems.

The photovoltaic solar inverter used for the system is the new Enewell-SOL P3A, which was released in 2023.

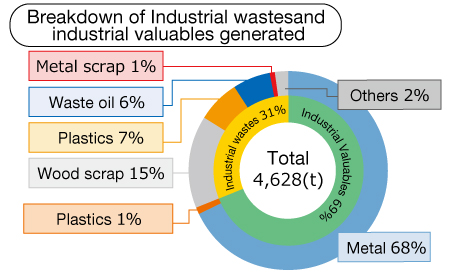

Resource Recycling and Resource Saving

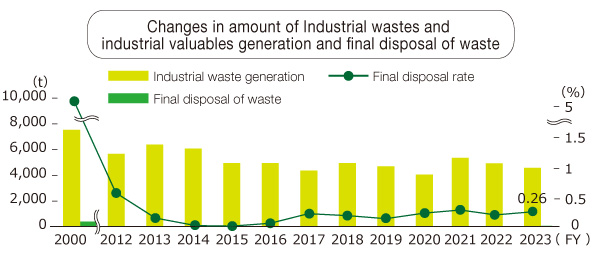

Recycling Activities

As a result of China’s plastic waste import restrictions, waste plastics, which were conventionally sold as valuable materials, are now classified as waste.

However, by selecting a recyclable waste disposal operator, we were able to maintain zero waste emissions.

Packing Materials Information

Policy on Water Usage

The Yaskawa Group recognizes that water is a limited resource and strives to protect water resources.

Water Usage Management

Water usage is monitored monthly to make sure that water leakage and other problems are detected early.

We promote the installation of real-time remote monitoring equipment when constructing new buildings.

Additionally, at our headquarters rainwater accounts for 97% of the total water amount used.

No violations or penalties occurred with regard to laws and regulations concerning water usage during FY2023.

Initiatives to Reduce Water Withdrawal

Our production processes do not rely heavily on water, and most of our water withdrawal is for human consumption and sanitary purposes.

We are working to reduce water withdrawal by taking measures against water leakage and switching to water-saving equipment.

In particular, we are actively promoting the use of water-saving toilets and other measures to reduce water consumption when constructing new buildings.

Evaluation of Water Risks

We evaluate water risks at the Yaskawa Group’s production plants in Japan and overseas using “Aqueduct”*1.

Evaluations indicated that six plants in China and one plant in India are located in high water stress areas.

In fiscal 2023, 28,500 m3 of water was withdrawn at sites located in high water stress areas, accounting for 11% of the entire Yaskawa Group.

Water storage tanks are installed at sites with risk of drought, and sandbags are placed at sites with risk of flooding.

*1: Water risks refer to the dangers and threats to corporate activities that may result from water pollution and water stress due to water shortages.

Initiatives of 3R(Reduce・Reuse・Recycle)

・Reuse of isopropyl alcohol (IPA)

High-purity IPA had been discarded from the Bestact Solutions’ Bestact manufacturing line in the Yukuhashi plant.

As a result of a review conducted by the group companies within Yukuhashi Plant, mainly centering on Yaskawa Electric, reuse of IPA was started because the quality of IPA used in Yaskawa Controls’s repair process could be ensured.

Consequently, the activities resulted in significant improvement in the amount of IPA discarded from 3,500 liters per year to 500 liters per year.

Region

Region

Principles & vision

Principles & vision

Procurement

Procurement

Sustainability for the Yaskawa Group

Sustainability for the Yaskawa Group

Customer satisfaction

Customer satisfaction

Supply chain

Supply chain

Social contribution

Social contribution

Compliance & risk management

Compliance & risk management