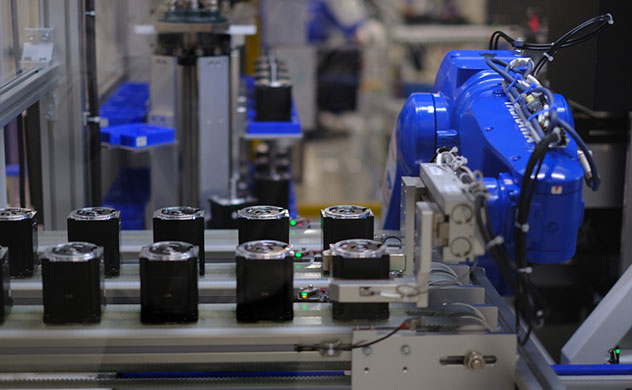

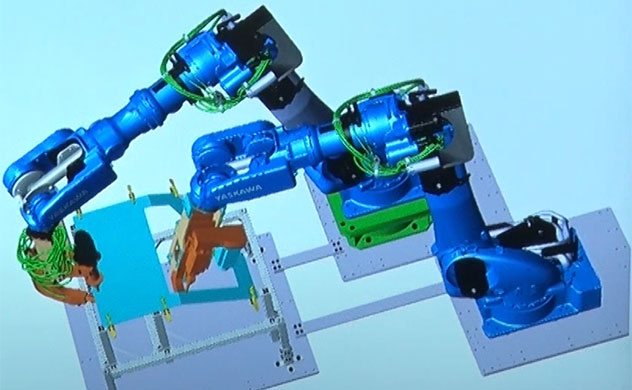

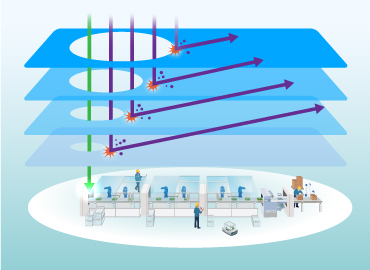

If an industrial robot stops unexpectedly on a factory line, the robot in the next step in the production sequence will also be unable to proceed. If this happens, the entire line stop when one robot stops. This is because when the robot is controlled in one direction by a controller such as a programmable logic controller (PLC), the robot can only perform the operations indicated in the order given. In order for robots to work autonomously and cooperatively with other robots, it is necessary for them to have the ability to think and judge for themselves. This type of manufacturing is called “autonomous decentralized manufacturing. “

By absorbing data such as torque value, vibration value, or temperature from the servo motor into the controller, the autonomy aspect of the robot is enhanced, and the robot can determine how to move if any other robot stops moving in the previous order.

Other solutions

-

Production

-

Quality

-

Maintenance