Customized monitor display and data utilization for each field role

-

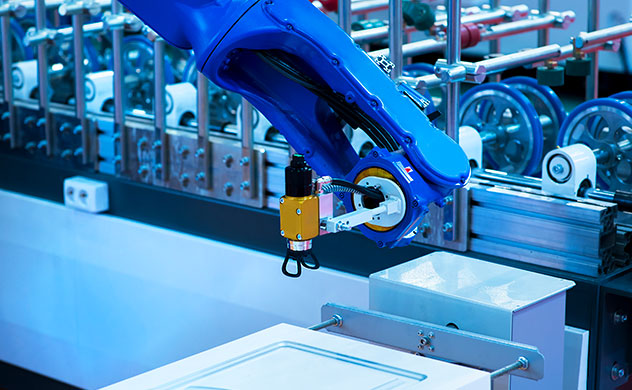

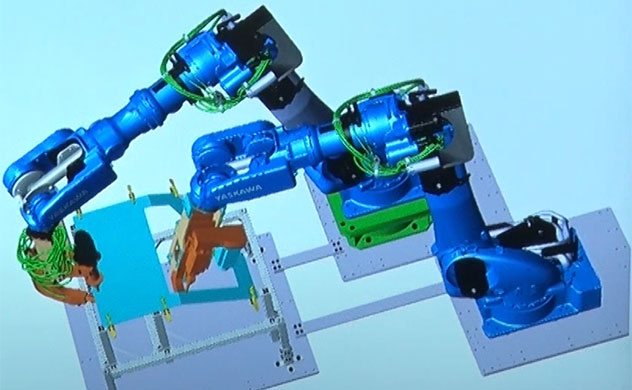

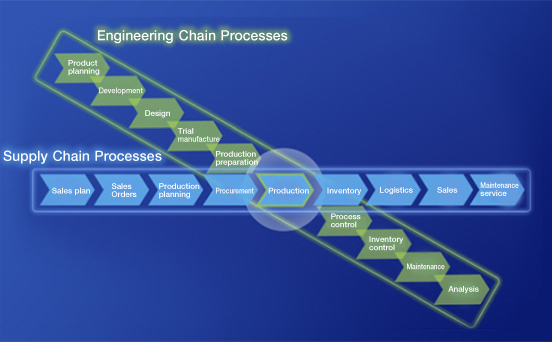

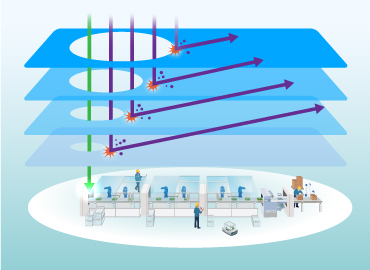

The i3-Mechatronics concept promoted by Yaskawa is the idea of visualizing the operating status of industrial robots and other production equipment, as well as the status of manufactured goods, and then using such data to improve production efficiency.

-

This operation data are a time series waveform of more than 100 types of minute data such as torque value, frequency, heat dissipation, and rotational speed generated mainly from servo motors installed in the devices in the cell area. In the case of a factory, data such as AMR or AGV position information (GPS value), which are used to supply parts, provide and transport finished products, and conduct the inspection process, are added to these data. On the other hand, the production management data include the percentage of progress in comparison with the production plan and the determination of “OK” or “No Good” products.

We recommend that customers manage their large datasets more efficiently by customizing the types of specific data they need. For example, in a factory, there are three primary roles: 1) an administrator who develops and manages a production plan, 2) an operator who monitors the progress of the process, and 3) maintenance to ensure that the operation is not hindered by sudden downtime, defects, or malfunctions. These responsibilities affect which data are required.

Next, if you are a production manager or administrator, you should understand the production plan and record, as well as the operation status and rate of the entire cell or each device. The focus will be to check the pace of production, whether there are any events or incidents that delay the planned production, and data that will enable smooth production.

If you are an operator observing the production process, you will look at data from the viewpoint of the actual production status. In the inspection before operation, the abnormality detection function is used to detect whether any abnormality occurs earlier than usual to prevent unexpected shutdown.

If you are responsible for maintenance, you must check if there is any equipment approaching the end of its lifespan. In addition to these lifespan monitors, the entire facility, such as conveyors, is preferentially maintained. By analyzing the data more deeply when a failure occurs, it is possible to investigate the cause, such as why it stopped, or if a failure occurred.

These customized views for each field role will enable you to efficiently manage the data with optimal viewing. By extracting data from a bird’s eye view rather than analyzing data by individual device, it becomes possible to provide the data requested by customers.

-

< Example of monitoring for administrator >

-

< Example of monitoring for operator >

-

< Example of monitoring for maintenance >

Other solutions

-

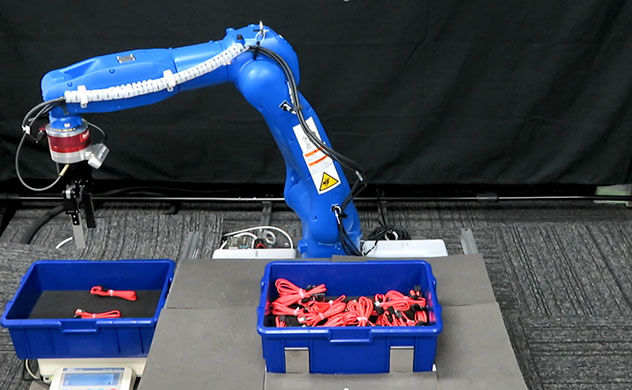

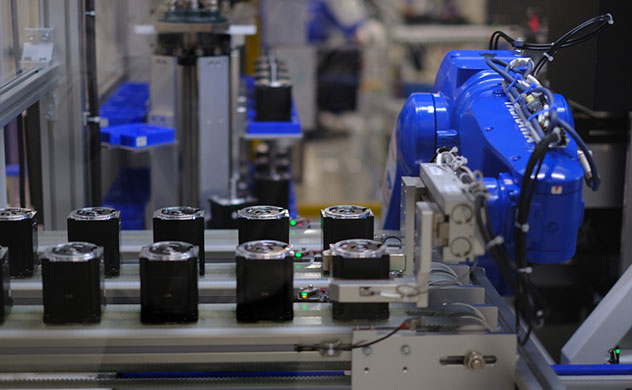

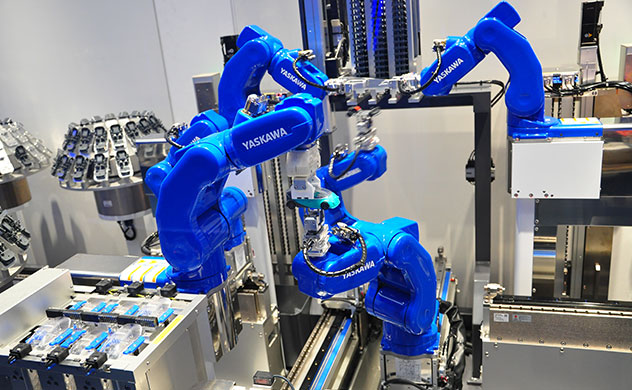

Production

-

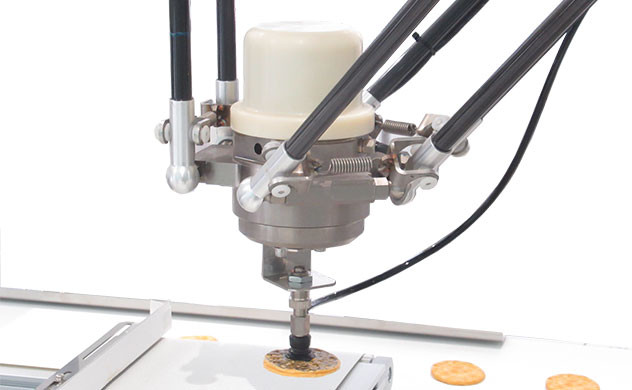

Quality

-

Maintenance