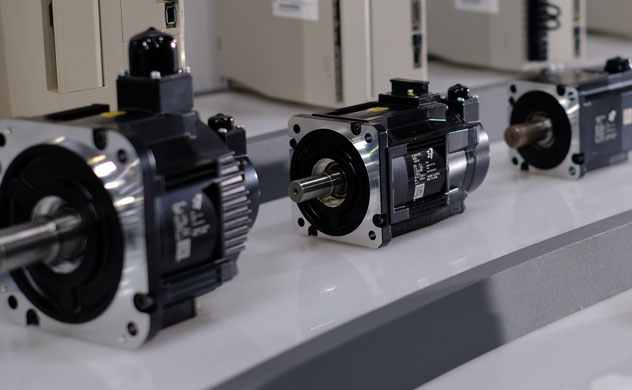

Yaskawa promotes i3-Mechatronics to help customers build smart factories. Servo motors are key components for visualizing the operation status of equipment and devices.

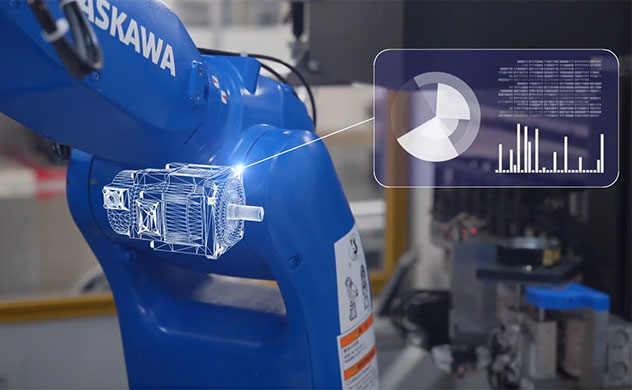

The servo motor itself acts as a sensor, and by using the YASKAWA Cockpit software tool, which collects, visualizes, and accumulates and analyzes data in a batch, it is possible to generate time-series process data such as speed, temperature, torque value, time, pressure, telecommunication quality, and disturbance at which equipment and industrial robots are operating for each process, and to monitor the status of equipment. There are hundreds of different types of data on a single production line, and this sensing data becomes the big data that supports IoT in the factory automation industry.

In the process of advancement in IoT at production sites by improving both the type and amount of big data detected from facilities and equipment, it will become easier to understand the operation status and identify factors at abnormal times. Yaskawa’s MP 3000 series machine controllers are equipped with a data logging function that records time series data, allowing time stamps in microseconds (1/1 million second). In addition, it is possible to identify which motor of which device stopped due to a malfunction when the line stopped unexpectedly by adjusting the time base of each device.