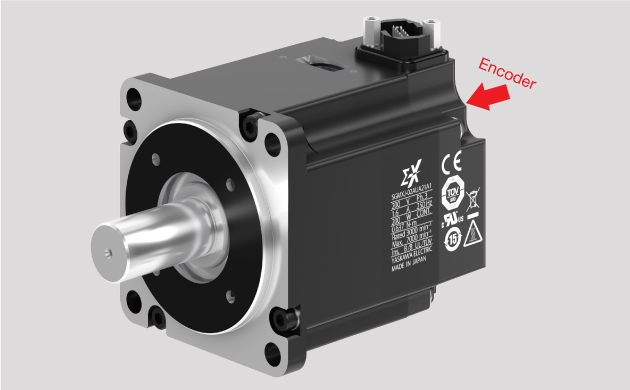

Positioning sensor “encoder” supporting ultra-high speed and ultra-precision performance

An encoder is essential component for servo drives to precisely control the movement of machines and equipment. The performance of the encoder is an important factor that influences the control performance of the servo motor, and consequently the performance of the machine and the equipment. The encoder angle information is used to control the motor rotation speed and rotation angle. The more accurate and detailed the angle information, the more precise you can control speed and position. Yaskawa’s latest servo motors “Σ -X series” have an encoder resolution of 26 bit, which is a detector, and can detect minute angles that are 1/67 million of 360 degrees.

Encoders also need to be downsized because they are incorporated into machines and equipment along with servo motors, and must have resistance against vibrations, shocks and temperature fluctuations even under the harsh operating environment.

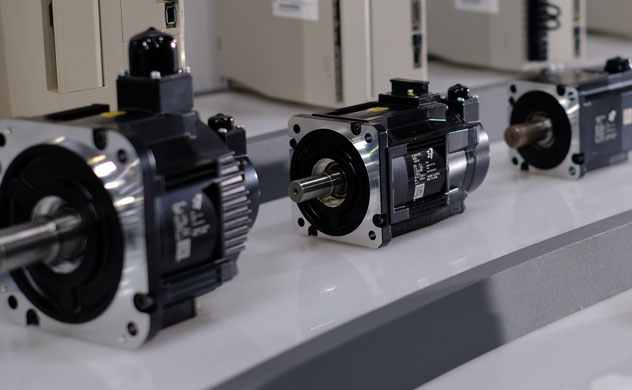

Servo amplifier that converts the output

Servo amplifiers are devices that enable ultra-precise motion control paired with servo motors. Amplifier is an abbreviation of “Amplifier”. In the case of audio equipment, it amplifies the signal, but in the case of servo amplifiers, it changes the energy of the supplied commercial power supply (100 V or 200 V) to the position/speed/torque command from the host controller, and converts the output so that the motor moves according to these commands. Yaskawa refers to servo amplifiers as Servo Pack.

Note 1: Servo Pack is a trademark of Yaskawa Corporation.

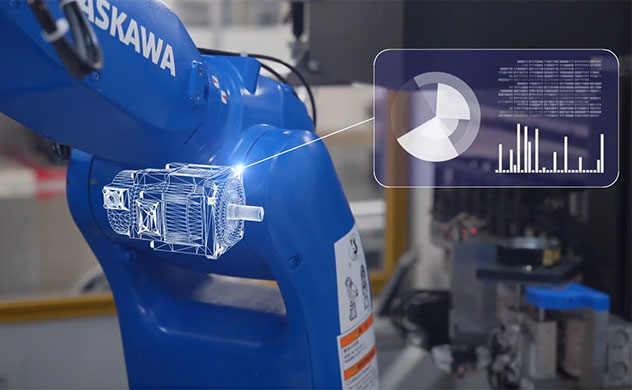

Machine controller, the brain of motion control

Generally speaking, various components such as servo motors, AC drive, display devices, switches and sensors are used in the equipment. A programmable logic controller (PLC) is used to control such equipment. PLCs are originally designed to replace electromagnetic relays used in conventional automated systems and perform control in a predetermined order. This is called sequence control. On the other hand, in recent years, various machines have been required to have higher performance. Machine controllers were created to control various devices that perform complex movements at high speed using servos and AC drive. In this way, machine controllers and PLCs were created for different purposes, so their specialties are different. While PLCs are good at controlling input and output (I/O), machine controllers are good at controlling complex motion control at high speed and with high accuracy.